Factory

POMINA FLAT STEEL FACTORY

+ 400

Skilled employees with high expertise, always prioritizing professional responsibility.

+ 100%

of the machinery and operating technology system is installed by Tenova Group, Italy - a leading brand in the global metal industry

+ 300

Modern equipment and machinery from advanced countries such as the United States, Italy, Germany, France, Japan, etc

To meet the increasingly high-quality product requirements of the market, Pomina Flat-Steel constantly innovates, heavily investing in machinery and equipment from leading European brands, contributing to helping customers realize their "Home Sweet Home".

Technology

The steel coil surface passes through HCL acid tanks to clean the steel rust layer, dirt, impurities on the surface. Then the steel coil is cleaned with water before being dried and coated with a protective chemical layer

The cold rolling line uses the principle of 6-reverse rolling mills, exerting pressure up to 1,300 tons on the steel coil surface to roll it thin into steel strips, with a rolling speed of up to 1,400 m/minute.

Investment in Tenova's most advanced heat treatment furnaces with automatic temperature control system, gas flow, strip speed throughout the galvanizing process

Anticipating future product trends with 3 drying furnaces and the most advanced heat sensor technology today

Machinery and Equipment

Brand: KURABO - Japan Function: Used to measure the thickness of the Antifinger coating on cold steel.

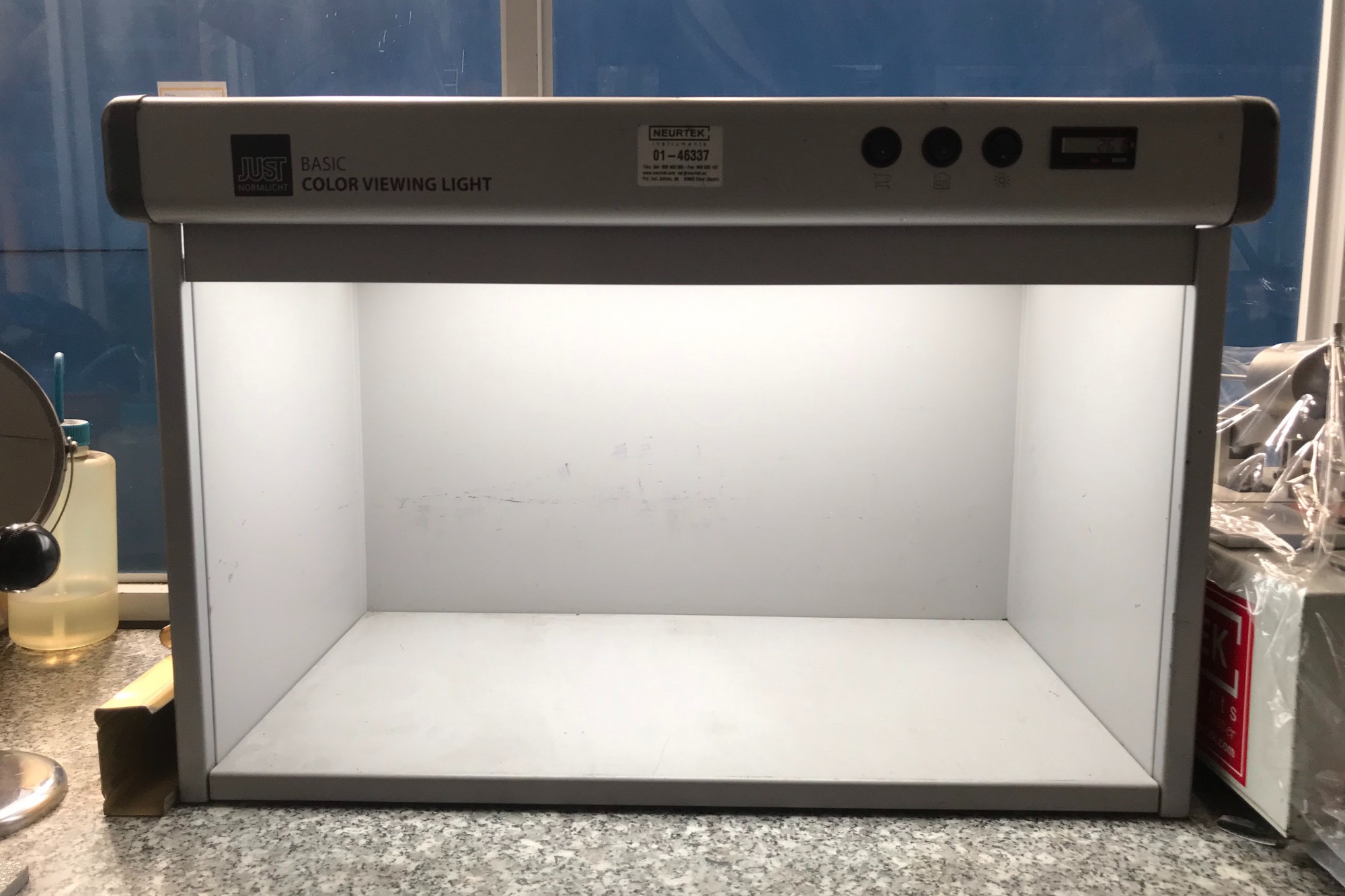

Brand: ERICHSEN - Germany Function: Comparing the color difference of the actual product with the agreed color by the customer with the manufacturer. The color-coated steel sample when produced in the color cabinet is visually inspected, achieving level 2, and the color deviation of the dental E colorimeter ...

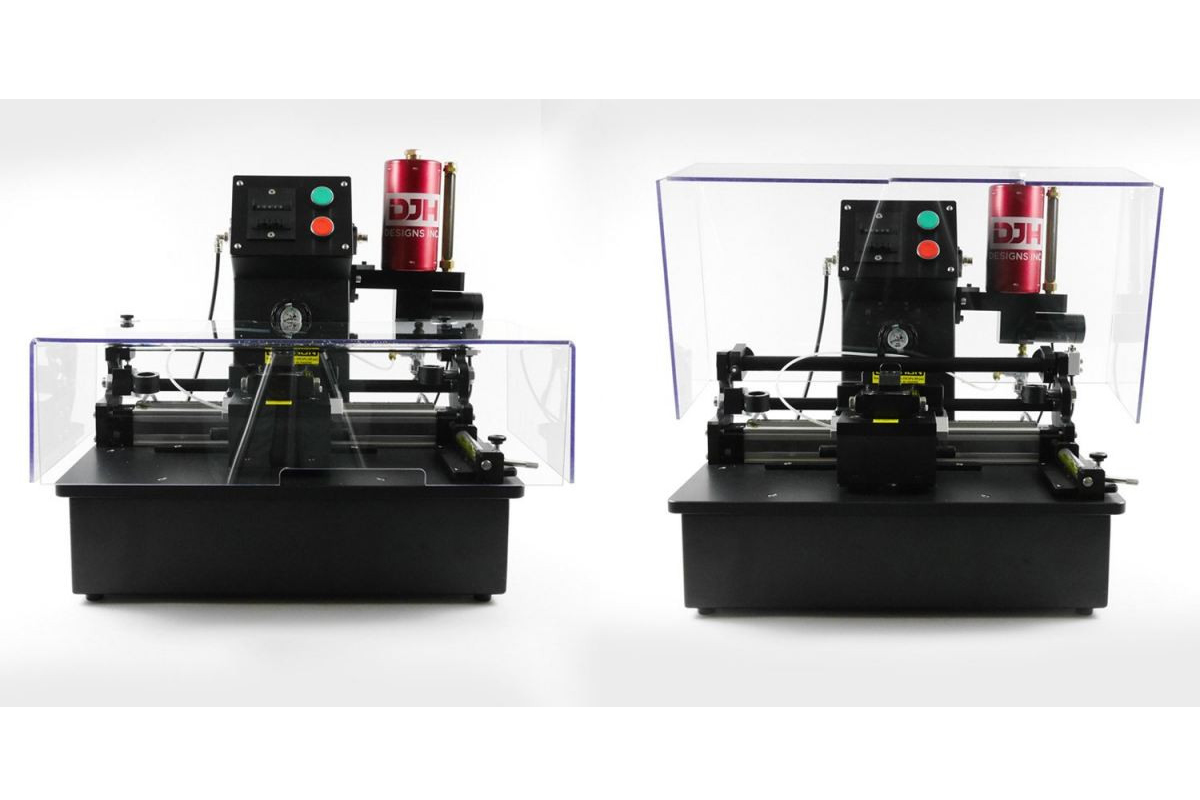

Brand: DJH - South Korea Function: Testing the solvent resistance paint durability by hammering with MEK solvent on both sides of the colored steel. The paint surface after hammering must remain intact, not peeling off, if the paint surface peels off, it is considered not passed.

Brand: TESTONE - South Korea Function: The paint layer is destroyed by a pencil with increasing hardness. The hardest pencil that does not scratch the paint layer will determine the hardness of the paint layer.

Brand: NEURTEK - Spain Function: Determines the scratch resistance of the paint layer on metal base steel (with aluminum-zinc alloy coating) using a pointed scratch test device.

Brand: NEURTEK Spain Function: Uses 3 basic colors to compare the color of the steel sample with the standard sample by naked eye (evaluated by eye through 5 levels).

Brand: TESTONE - South KoreaFunction: Determine the adhesion of the paint layer on the metal base after creating a dent with a scratch mark.

Brand: NEURTEK - Spain Function: Using a heavy object (ball head) to determine the ability of the paint layer to resist cracking/peeling due to rapid impact

Brand: DJH - South KoreaFunction: Machine measures the paint thickness of color-coated steel.

Brand: SPECTRO - Germany Function: Metal analysis machine, analyzing the elements in aluminum-zinc alloy, hot roll...

Brand: NEURTEK - SpainFunction: Machine used to test tensile strength, yield limit, elongation of stee

Brand: SHIMADZU - JapanFunction: Machine used to test tensile strength, yield limit, elongation of steel samples.