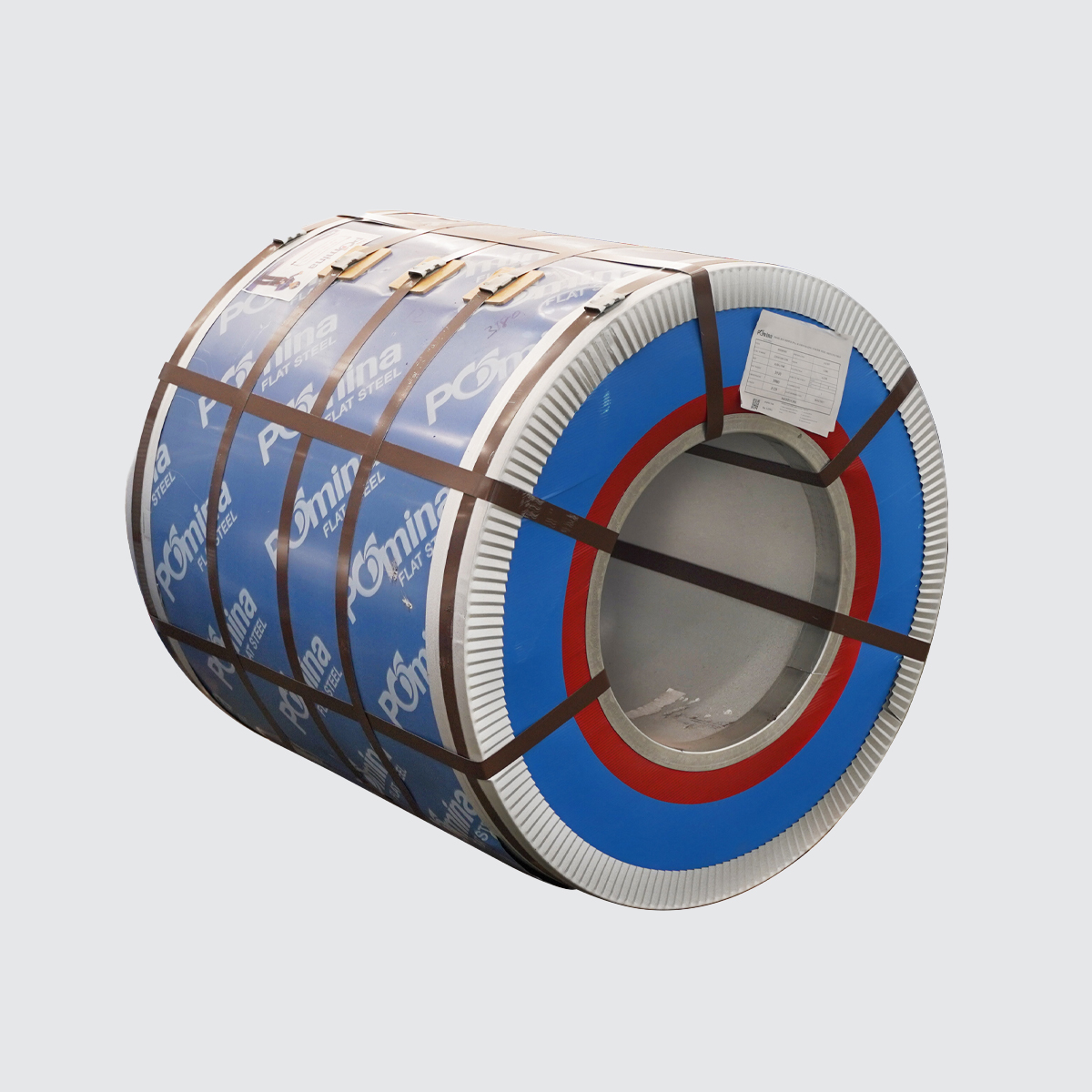

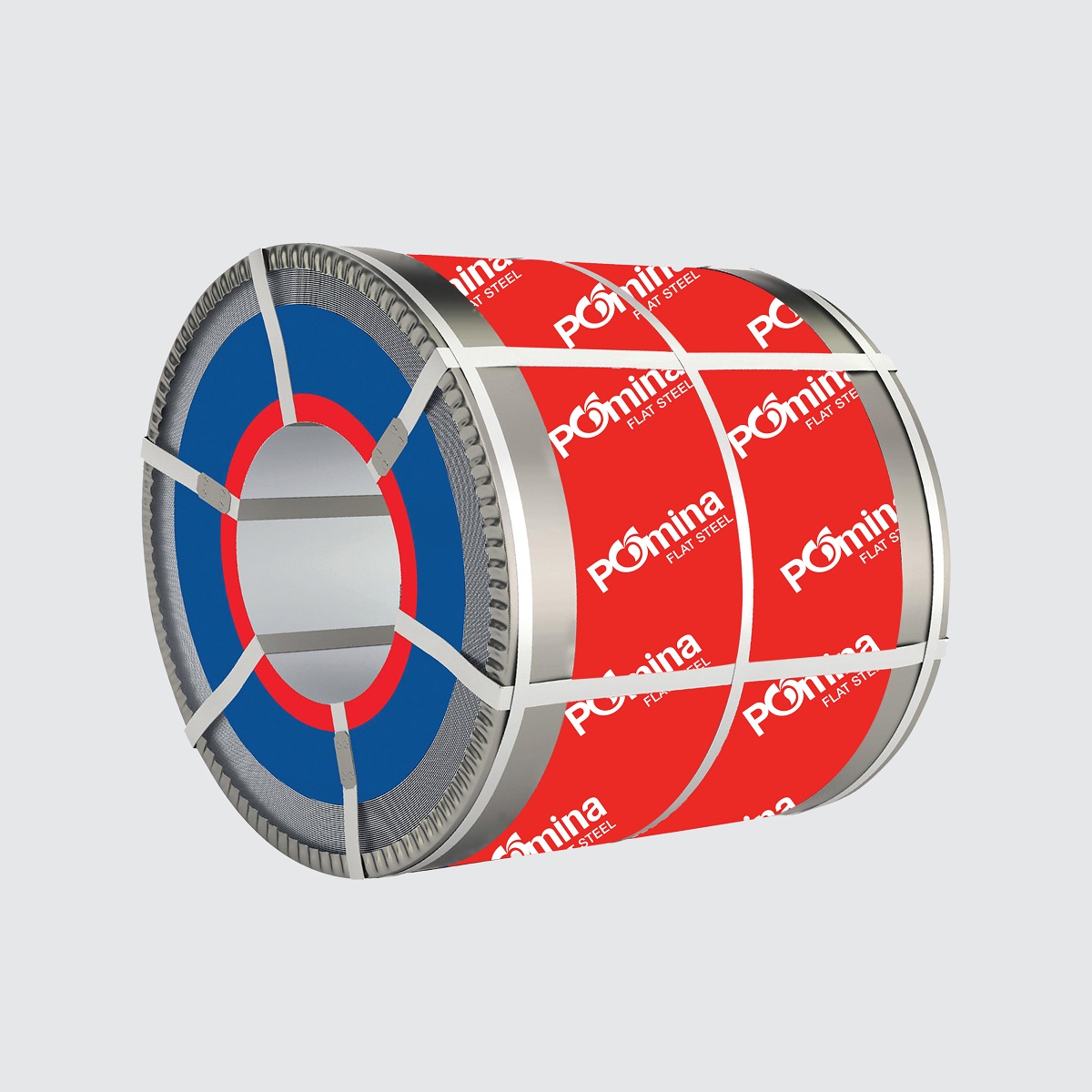

Hot dip Galvanized Steel Coil is also known as galvanized steel or galvanized coll-rolled coil. Galvanized steel coil is highly resistant to corrosion in the natural environment. The product is commonly used for the civil construction or industrial construction, such as roofing, partitions, floor coverings and other applications...

Hot dip Galvanized Steel Coil is manufactured through a process that involves cold-rolled coils passing through a galvanizing line, which includes surface cleaning and annealing in NOF furnaces to modify the mechanical properties of the steel. Subsequently, a layer of zinc alloy is applied using the hot-dip galvanizing method with air-knife technology, and finally, the surface is coated with an anti-oxidation protective chemical layer.

CONTACT FOR ORDERING

Description

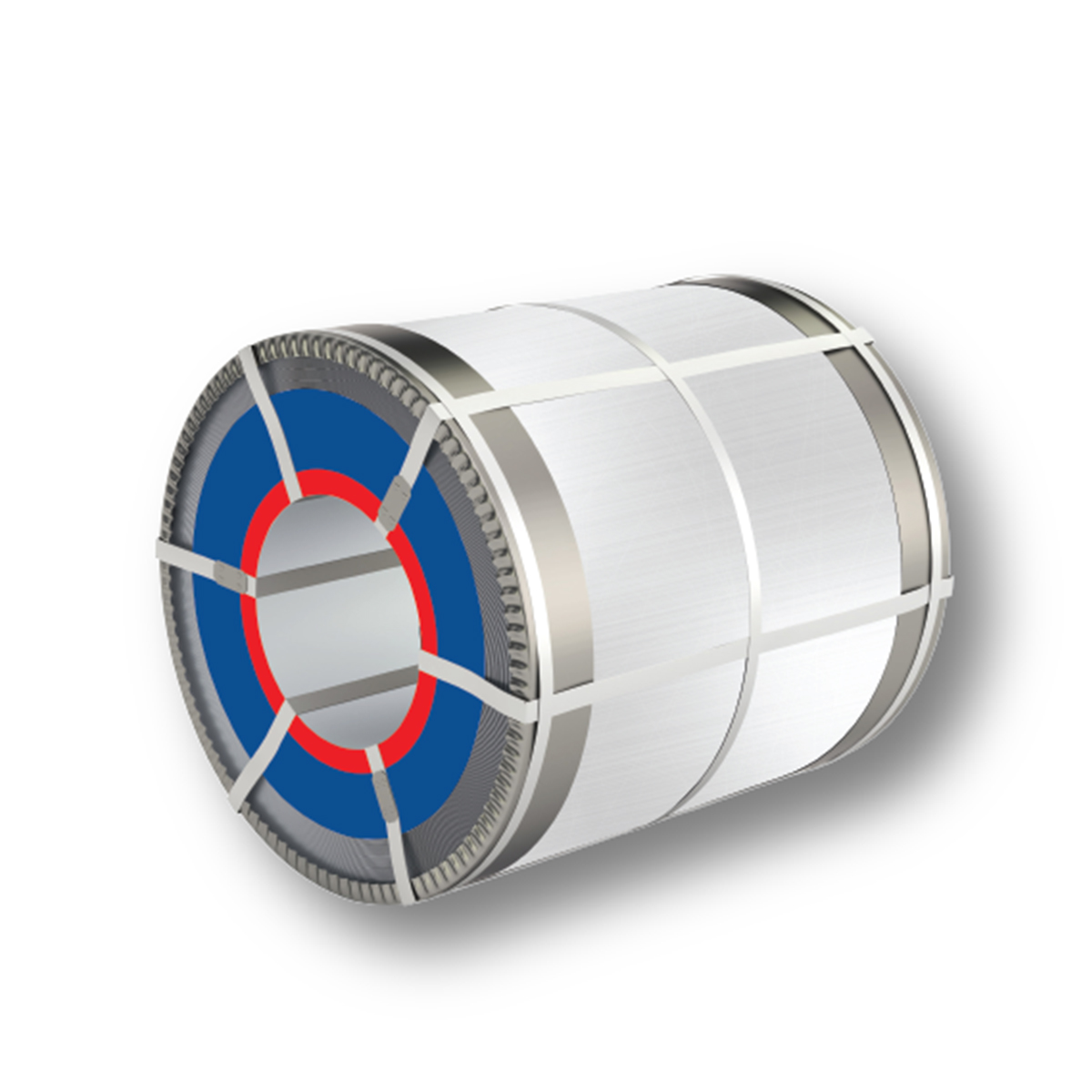

Structure of Hot Dip Galvanized Steel Coil (GL)

Hot dip Galvanized steel coil (GI) is also known as galvanized steel or cold-rolled steel coated with zinc. This is a product with high corrosion resistance in natural environments, often used in the construction and civil industry (such as roofing sheets, partition walls, floor coverings, and other applications). The production process of galvanized steel originates from cold-rolled steel through a zinc coating line with stages such as cleaning the surface, annealing in the NOF furnace to alter the steel properties. Then, they are coated with a layer of zinc through the hot-dip galvanizing process with air knife technology and finally an additional protective layer against oxidation such as chrome.

Technical Specifications of Hot Dip Galvanized Steel Coil (GL)

- Finished surface: glossy, bright, regular spangle.

- Bending strength (T-bend): 0÷3 T

- Coating weight (g/m²): Z80 - Z275

- Coating composition: 99.0%/Zn

- TCT thickness: 0.25 - 2.00 mm

- Density kg/m: 2.25 - 18.70

Applications of Hot Dip Galvanized Steel Coil (GL)

Hot Dip Galvanized Steel Coil (GL) is produced in various sizes and thicknesses for widespread use in different industries. Specifically:

- Used in manufacturing partition walls, roofing sheets, membranes, etc.

- Utilized in the production of electronic devices, rice cookers, refrigerators, TVs, washing machines, industrial products, drainage systems, ventilation; automotive spare parts, motorcycles; etc.

- In traditional fields, galvanized steel is used to make various types of outdoor signs, billboards, or to create rolling doors, sliding doors, etc.

Introduction Video

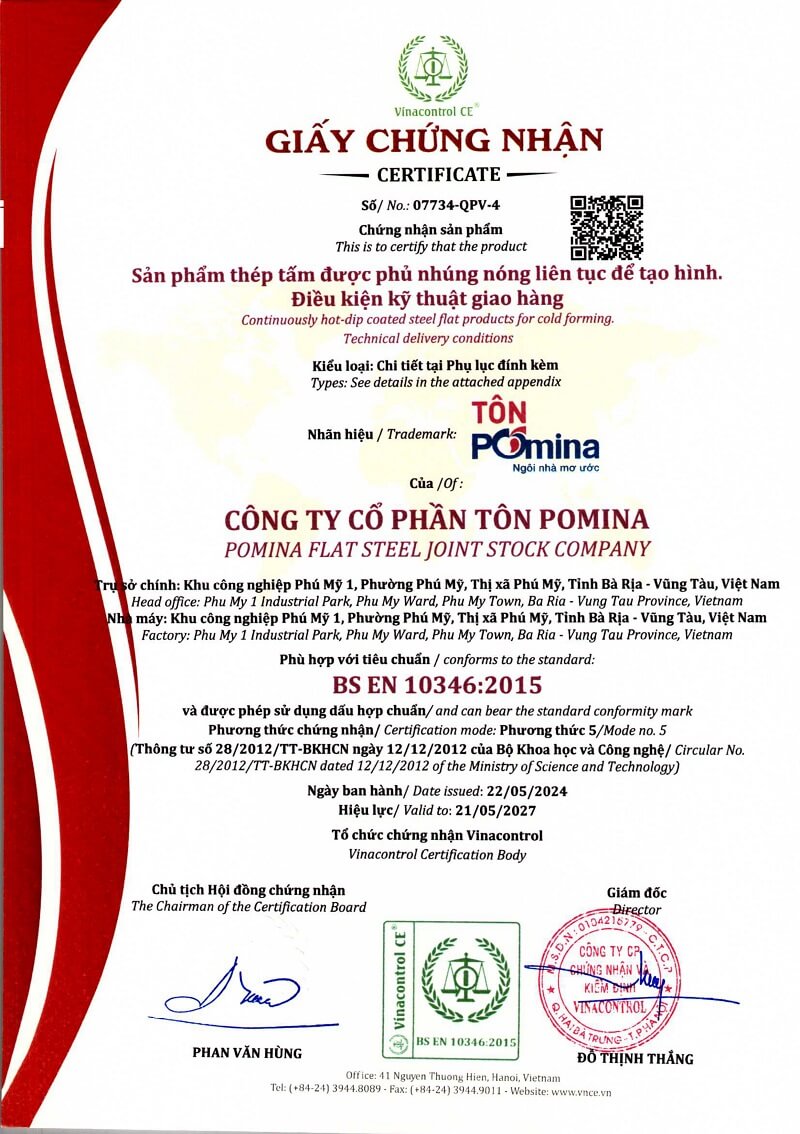

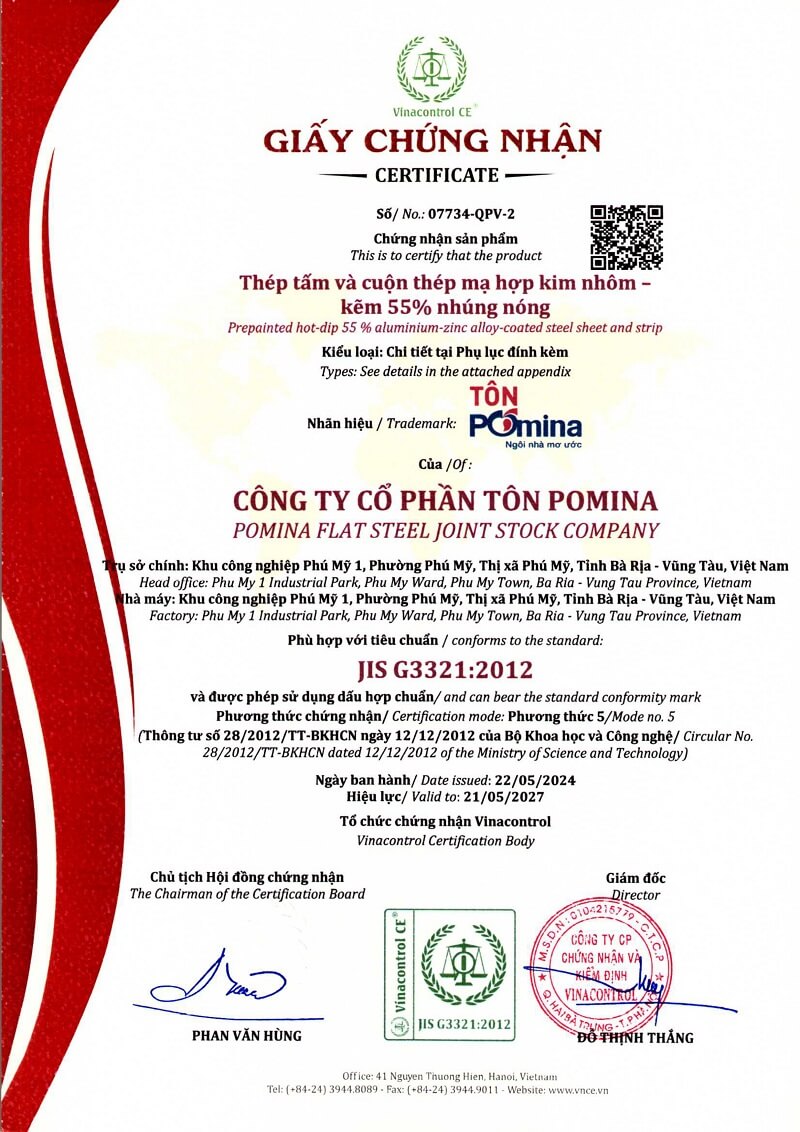

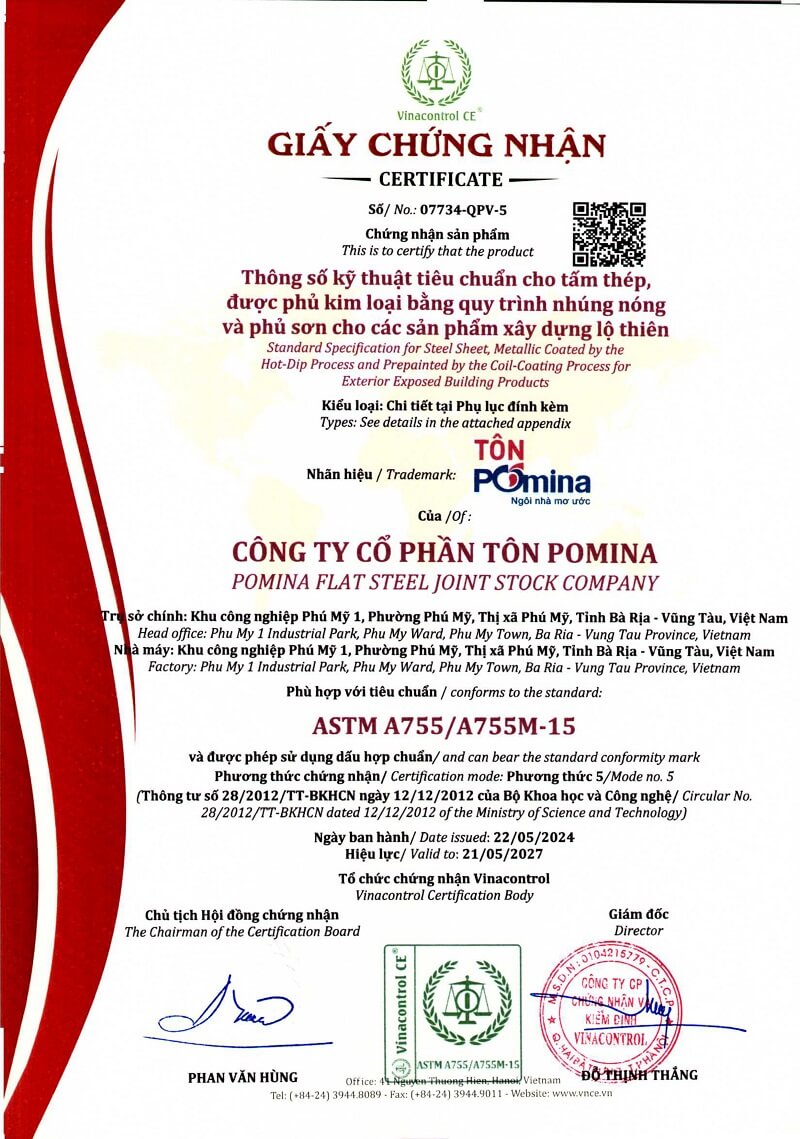

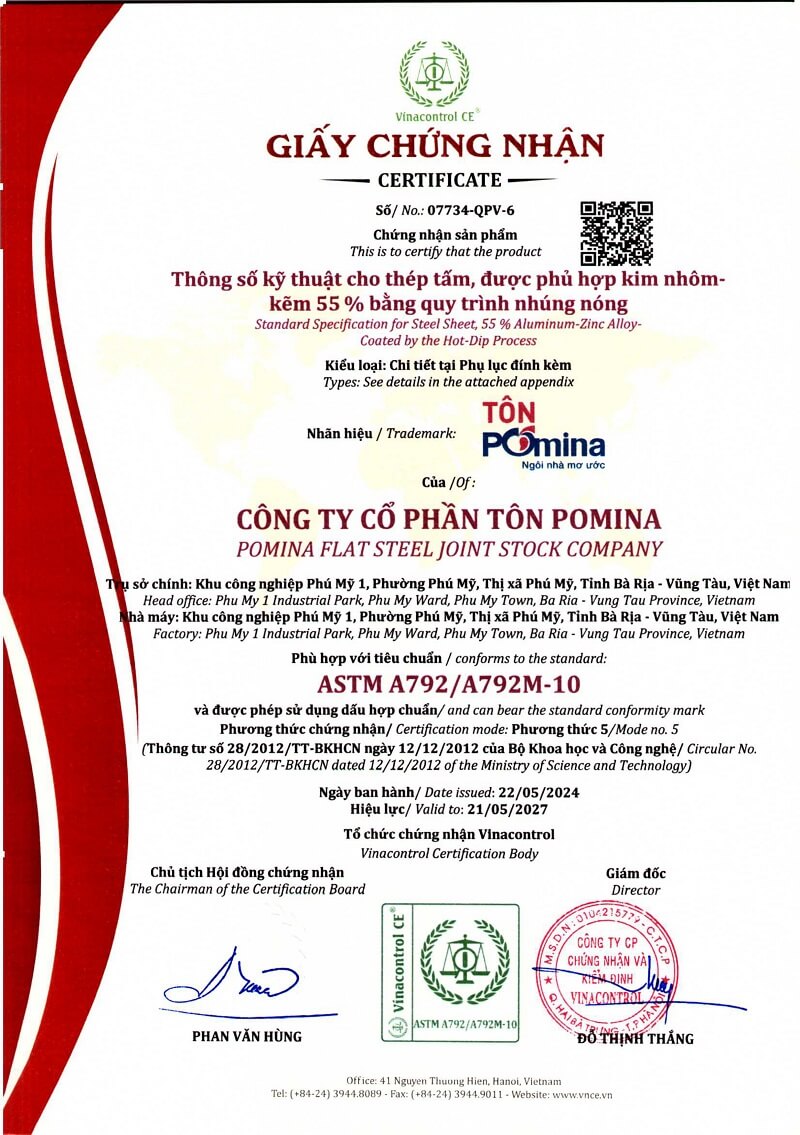

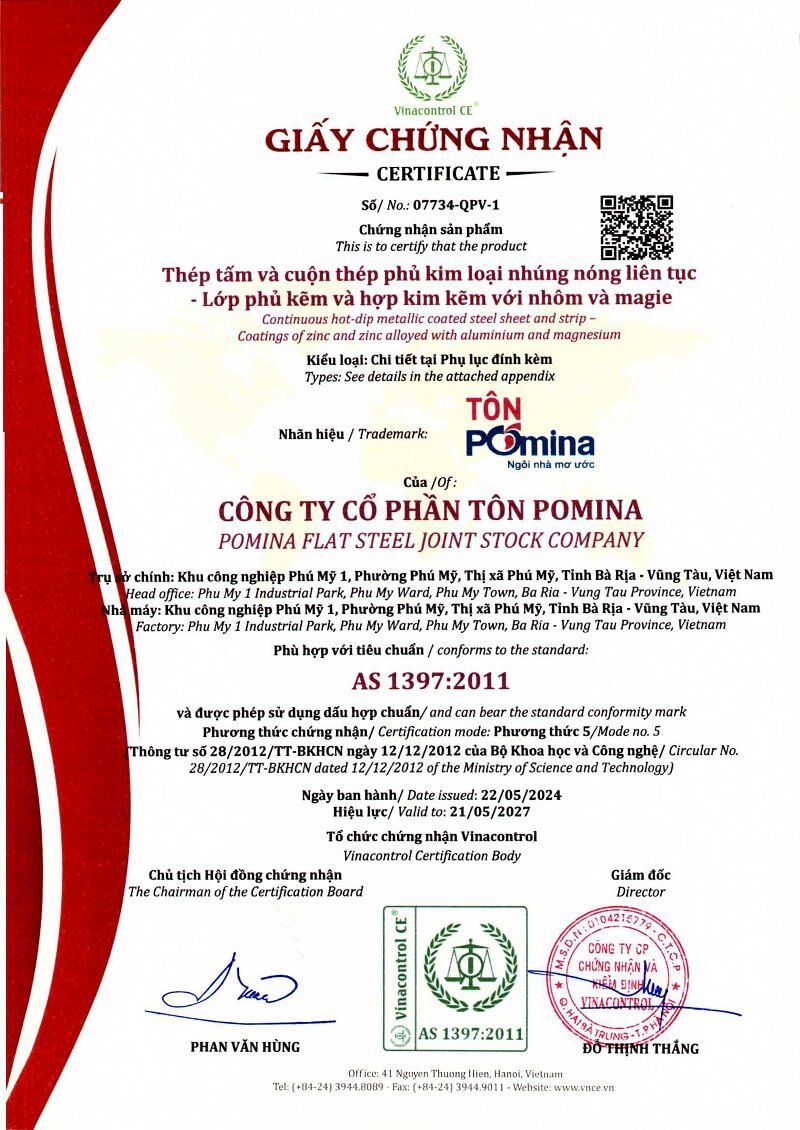

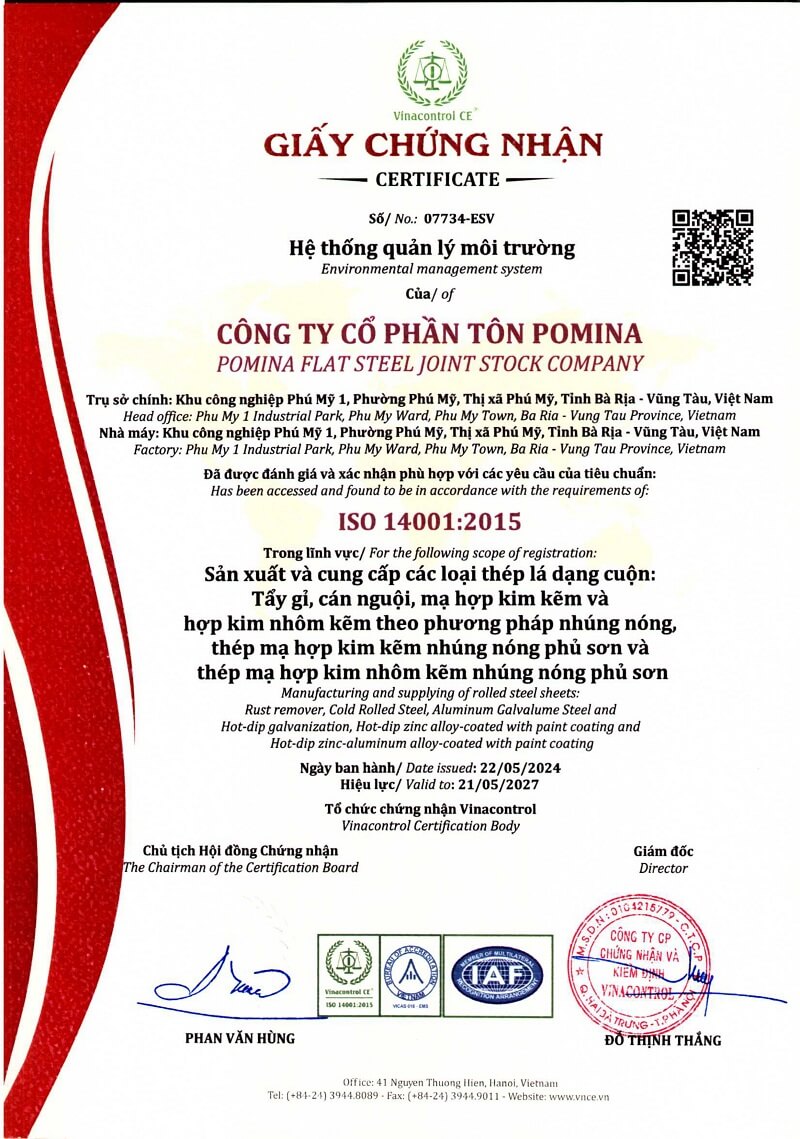

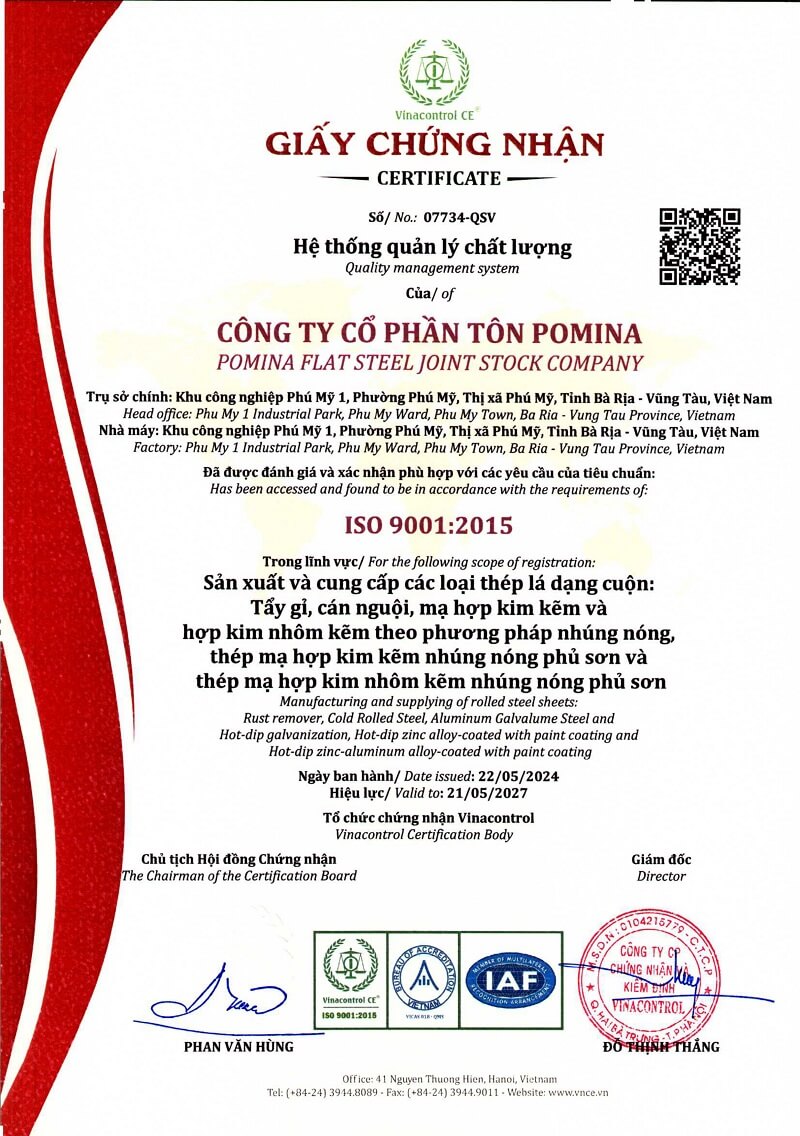

Product Certifications

Frequently Asked Questions

Galvanized steel, also known by many other names such as galvanized sheet, galvanized steel, galvanized coil, galvanized steel, galvanized cold-rolled steel, galvanized sheet metal. This product is essentially a metal sheet steel coated with a zinc oxide layer to prevent corrosion during the hot-dip galvanizing process, enhancing its durability.

- Galvanized steel has a smooth and shiny surface after production, making it always look glossy, beautiful, and easy to clean.

- The product has high corrosion resistance due to an additional zinc layer, providing good protection when used outdoors or in environments with hazardous chemicals.

- It has high impact resistance and durability due to the zinc coating, resulting in a long lifespan of up to 50 years without maintenance.

- Galvanized steel is lightweight and easy to transport for construction purposes.

Galvanized steel is divided into 3 main types:

-

Flat galvanized steel with a smooth glossy surface, commonly used in industries and machinery manufacturing.

-

Square wave galvanized steel: This is a type of thin steel sheet rolled and embossed to enhance aesthetics. Currently, square wave galvanized steel comes in wave steps such as: 5 waves, 6 waves, 7 waves, 9 waves, 11 waves.

-

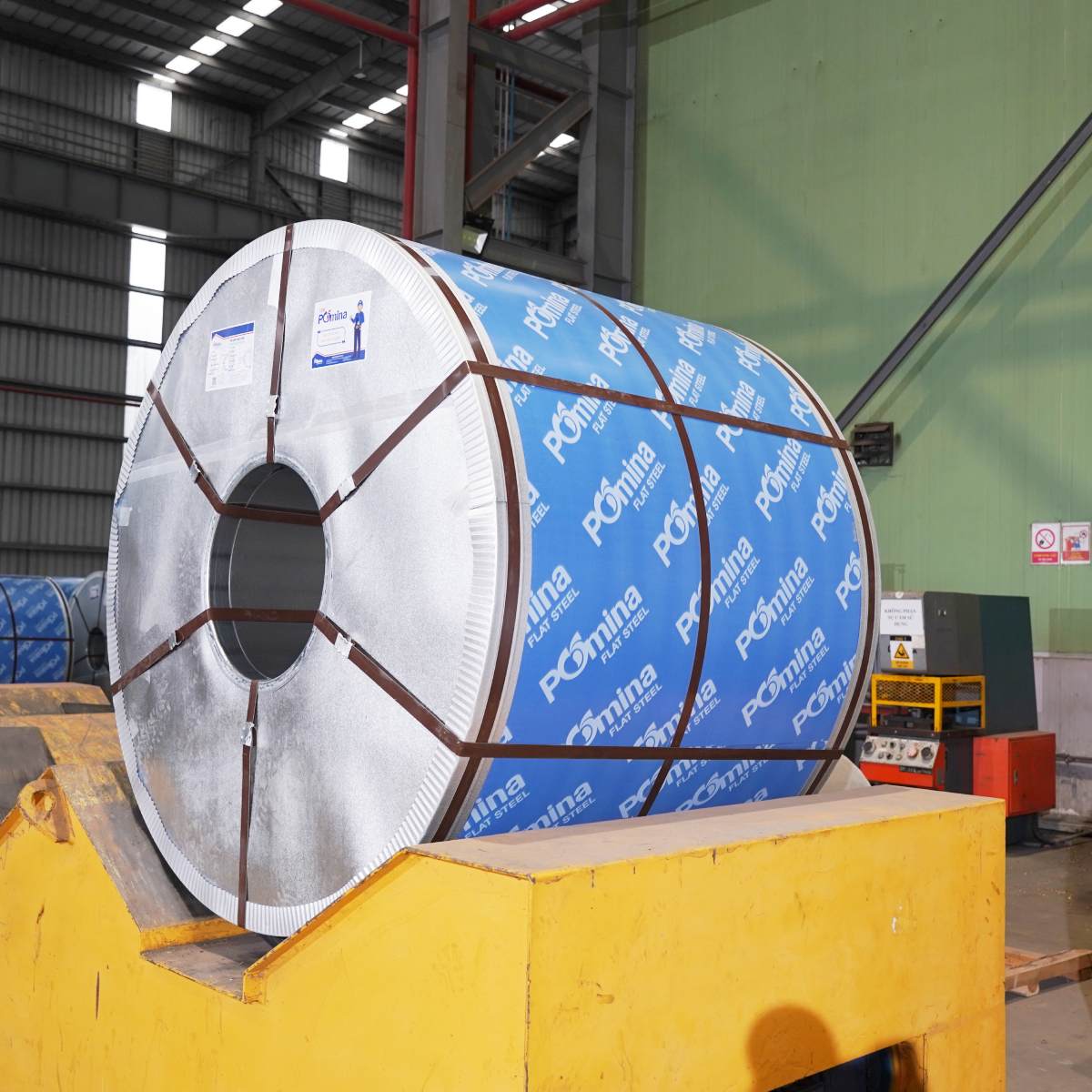

Galvanized coil steel: This is a round coil-shaped aluminum-zinc alloy galvanized steel with high durability.

To purchase genuine galvanized steel coils from Pomina Flat-Steel, you can place an order directly on the website: https://pomina-flat-steel.com/en/

The sales department of Pomina Joint Stock Company will contact you directly for consultation and quotation.

You can also buy directly at over 300 distribution points/rolling and cutting agents across all 3 regions of the country of Pomina galvanized steel at: https://pomina-flat-steel.com/en/distribution-system.html

In addition, you can also contact the toll-free hotline of Pomina Flat-Steel: +84 906 687 917 to get immediate support for purchasing addresses as well as prices near your province/city.

Other Products

- Price per meter (width 1.2m): WhapsApps: (+84) 938 358 971

- Number of colors: 6

- Thickness: 0.25 - 0.45mm

- Warranty:

- Applications: roofing and wall cladding, factories and warehouses, manufacturing mechanical products, automotive industry, interior and exterior decoration.

- Price per meter (width 1.2m): WhapsApps: (+84) 938 358 971

- Number of colors: 0

- Thickness: 0.25 - 0.6 mm

- Warranty: 5 - 10 - 15 years

- Applications: Civil construction, grade 4 houses...

- Price per meter (width 1.2m): WhapsApps: (+84) 938 358 971

- Number of colors: 0

- Thickness: 0.25 - 0.6 mm

- Warranty: Anti-corrosion warranty: 15 years, 20 years

- Applications: Residential buildings, coastal farms, riverbanks...

- Price per meter (width 1.2m): WhapsApps: (+84) 938 358 971

- Number of colors: 6

- Thickness: 0.35 - 0.6 mm

- Warranty: 8 years Fading warranty; 15 years Anti-corrosion warranty

- Applications:

- Price per meter (width 1.2m): WhapsApps: (+84) 938 358 971

- Number of colors: 6

- Thickness: 0.25 - 0.6 mm

- Warranty: Anti-corrosion warranty: 10 -15 years; Fading warranty: 5 - 8 years.

- Applications: Roof panels, partition walls

- Price per meter (width 1.2m): WhapsApps: (+84) 938 358 971

- Number of colors: 6

- Thickness: 0.4 - 0.6 mm

- Warranty: 10 years Fading warranty; 20 years Anti-corrosion warranty

- Applications: Key projects, industrial projects

- Price per meter (width 1.2m): WhapsApps: (+84) 938 358 971

- Number of colors: 6

- Thickness: 0.4 - 0.6 mm

- Warranty: 10 years Fading warranty; 20 years Anti-corrosion warranty:

- Applications:

- Price per meter (width 1.2m): WhapsApps: (+84) 938 358 971

- Number of colors: 7

- Thickness: 0.35 - 0.6 mm

- Warranty: Fading warranty: 8 year; Anti-corrosion warranty: 12 years

- Applications: Thai-style roofs, Japanese-style roofs, villas...

- Price per meter (width 1.2m): WhapsApps: (+84) 938 358 971

- Number of colors: 6

- Thickness: 0.25 - 0.6 mm

- Warranty: 5- 10 years Anti-corrosion warranty - 3 - 5 years Fading warranty

- Applications: Residential buildings, grade 4 houses…