CONTACT FOR ORDERING

Description

Structure of Cold-rolled coil (CRC)

Cold rolled steel is produced from hot rolled coil (HRC) as follows: Hot rolled steel is passed through a pickling line to remove the rust layer on the surface, then it is cleaned and coated with an oil layer to protect the surface.

Hot rolled steel after pickling and oiling is called pickled and oiled (PO) steel. Pickled and oiled steel is then sent to the cold rolling line to produce cold rolled steel products with custom sizes.

Advantages of Cold-rolled steel coil

- This type of steel has high mechanical properties with standard hardness, high strength, excellent load-bearing, and impact resistance.

- The surface of the steel always achieves a smooth finish and high gloss.

- Especially, the steel has a very eye-catching bright color, low carbon content which helps the steel have higher durability.

Applications of Cold-rolled coil

Cold rolled steel products have many outstanding characteristics, so the application of cold rolled steel in the construction industry is very diverse. In addition to being used as a semi-finished product to produce galvanized steel, cold-rolled steel, or colored cold-rolled steel, due to its high durability and specific properties requiring good load-bearing characteristics, cold rolled steel also meets the requirements of many applications such as:

- Used extensively in making toolboxes, racks, lights, and staircases.

- Metal furniture such as wardrobes, beds, aluminum door frames.

- Manufacturing specialized construction machinery equipment.

- Framework for construction projects ensuring long-term durability and high quality.

- Machine parts for deep drawing and stamping.

- Auto parts, aircraft components.

Introduction Video

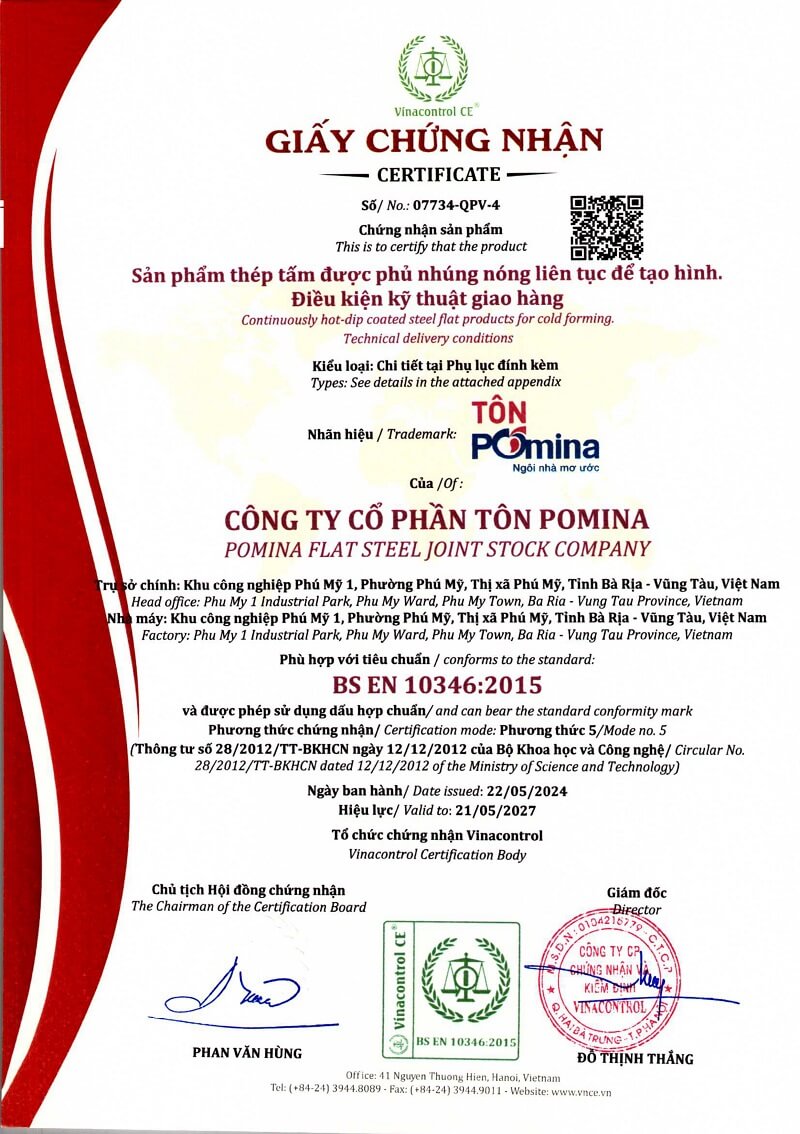

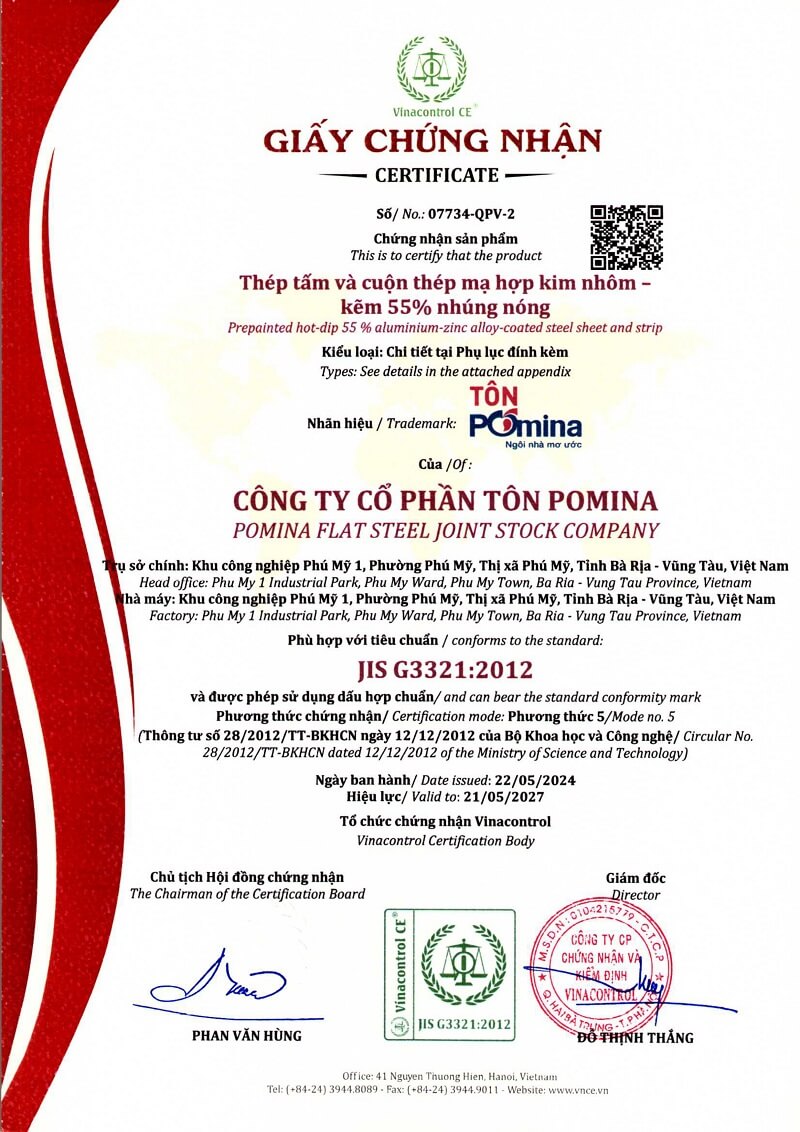

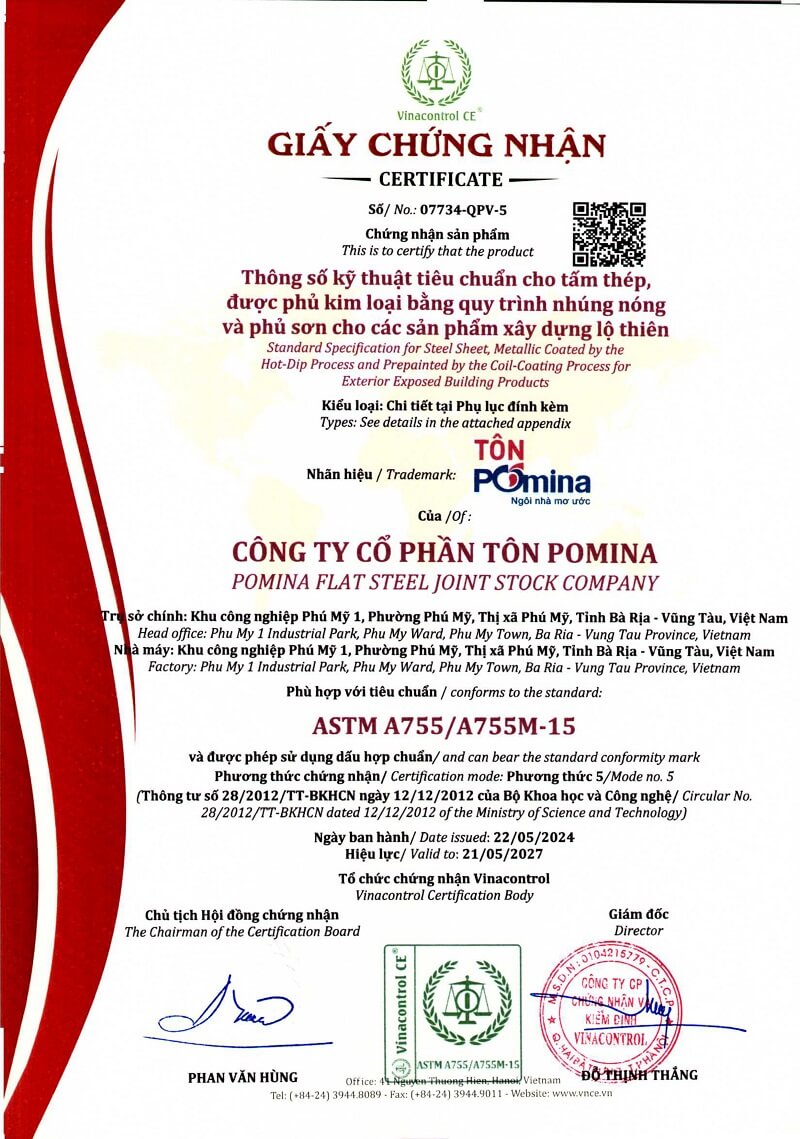

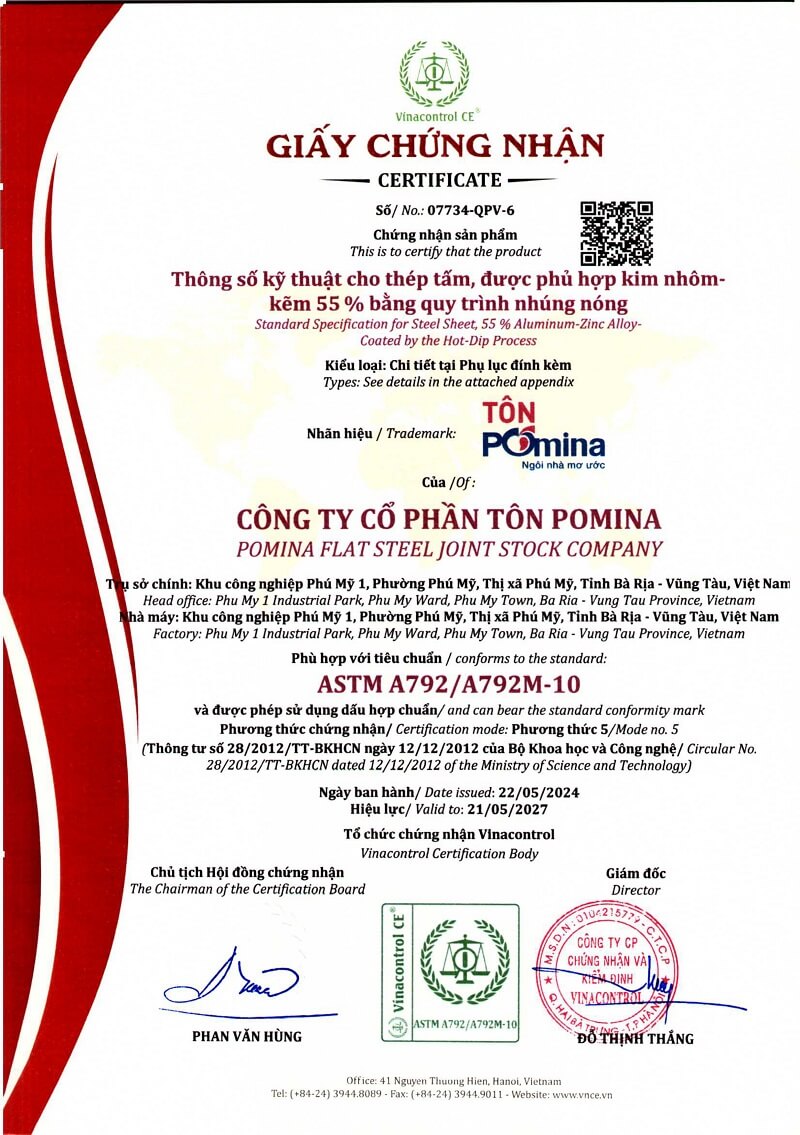

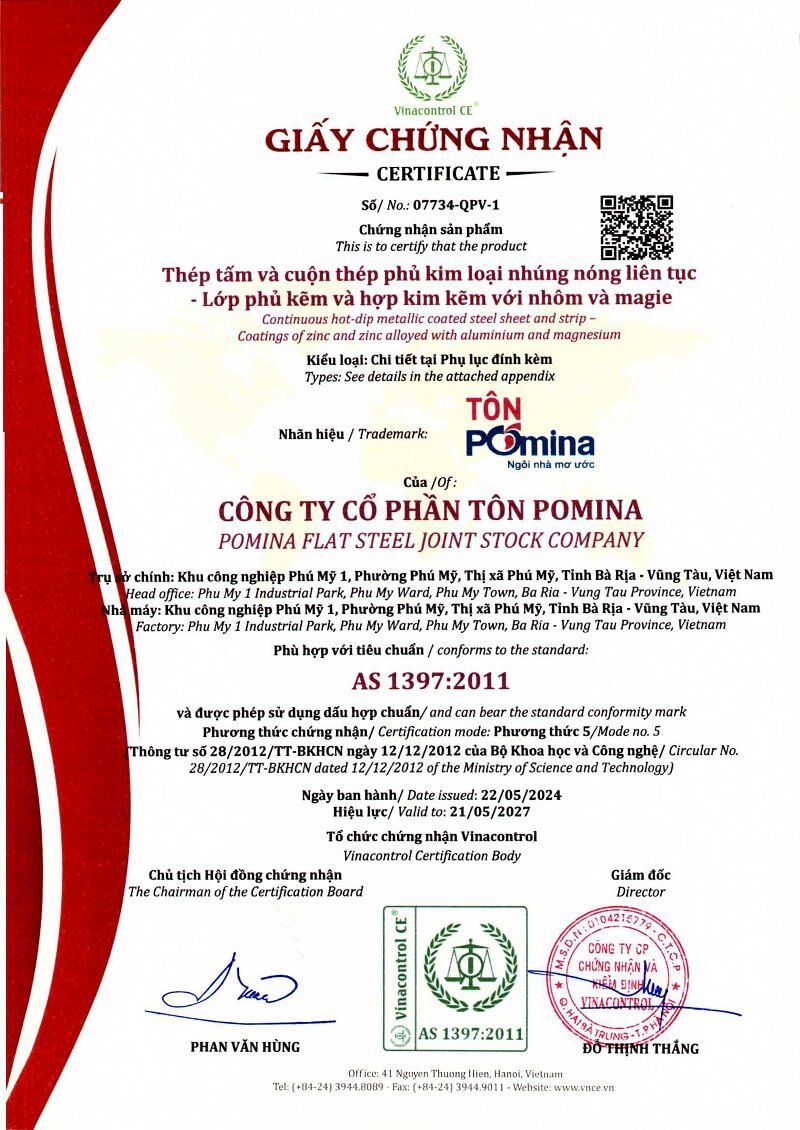

Product Certifications

Frequently Asked Questions

What is cold rolled coil steel? This is hot rolled steel that has been processed, cooled to room temperature, in order to produce precise dimensions with higher strength. After being cooled, it is often recoiled for easy transportation and rolling, hence it is also called cold rolled coil steel.

Cold rolled coil steel is abbreviated as CR: Cold rolled or CRS: Cold rolled steel. Cold rolled steel is the final stage in steel manufacturing; the steel billet will be passed through rollers, presses, and rolls. After the billet is cooled, the thickness of the cold rolled steel will gradually decrease as it passes through the rollers. Cold rolled steel is rolled at a low temperature, approximately at room temperature. The product is sent through a line to remove rust on the surface, then the surface is cleaned and coated with oil for protection.

To purchase genuine cold rolled coil steel products from Pomina Flat Steel, you can place orders directly on the website: https://pomina-flat-steel.com/en/

The business department of Pomina Joint Stock Company will contact you directly for consultation and pricing.

You can also purchase products directly at over 300 distribution systems/rolling and cutting agents across the country at Pomina Flat Steel's website: https://pomina-flat-steel.com/en/distribution-system.html

Furthermore, you can also contact Pomina Flat Steel's toll-free advisory hotline: (+84) 906 687 917 for immediate assistance with purchasing locations and prices near your province or city.

The price of cold rolled steel or cold rolled coil steel is one of the topics of great interest to customers. Please contact the hotline 0906687917 immediately for the most accurate price quote from Pomina Flat-Steel.

| Criteria | Hot Rolled Steel | Cold Rolled Steel |

| Accuracy | Accuracy is not as high as cold rolled steel | Due to cooling, the finished product's size will be more accurate |

| Cost | Lower than cold rolled steel | Finished product is higher priced, but in return, it has higher durability |

| Typical thickness | 0.9mm and above | 0.15mm - 2mm |

Color |

Surface is slightly rough with a grayish-blue color (billet) | Surface is smooth and gray in color (steel sheet, steel plate) |

| Storage | Can be stored outdoors without packaging | Requires packaging and indoor storage |

Both hot rolled steel and cold rolled steel have their own advantages. Therefore, both hot rolled steel and cold rolled steel are applied in construction.

Other Products

- Price per meter (width 1.2m): WhapsApps: (+84) 938 358 971

- Number of colors: 0

- Thickness: 0.23 - 0.5 mm

- Warranty:

- Applications: Mechanical engineering and construction industry, galvanized steel production, etc.