Information

1. What is Pickled & Oiled Steel (PO) ?

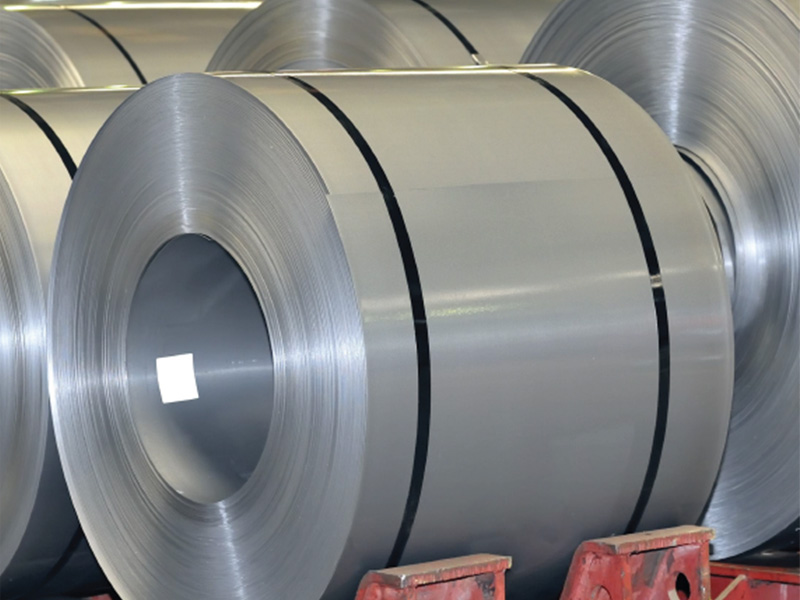

PO (Pickled & Oiled Steel) is a cold-rolled steel that has been processed through an acid pickling process to remove the iron oxide layer. Then, a thin layer of industrial oil is coated to prevent oxidation during storage and transportation. Product structure includes:

- Steel grade: G300 – G550 depending on application requirements

- Surface treatment: clean pickling + protective oil coating

- Thickness: from 0.30mm to 0.50mm

- Width: 914mm – 1,200mm

2. Pickled & Oiled Steel (PO) production process

- Step 1 – Pickling: Hot-rolled steel coils will be passed through the pickling line to remove the rust layer on the steel surface

- Step 2 – Oil coating: After the hot-rolled steel coil has completely dried on the surface, the product is cleaned and coated with an additional layer of oil to help protect the surface

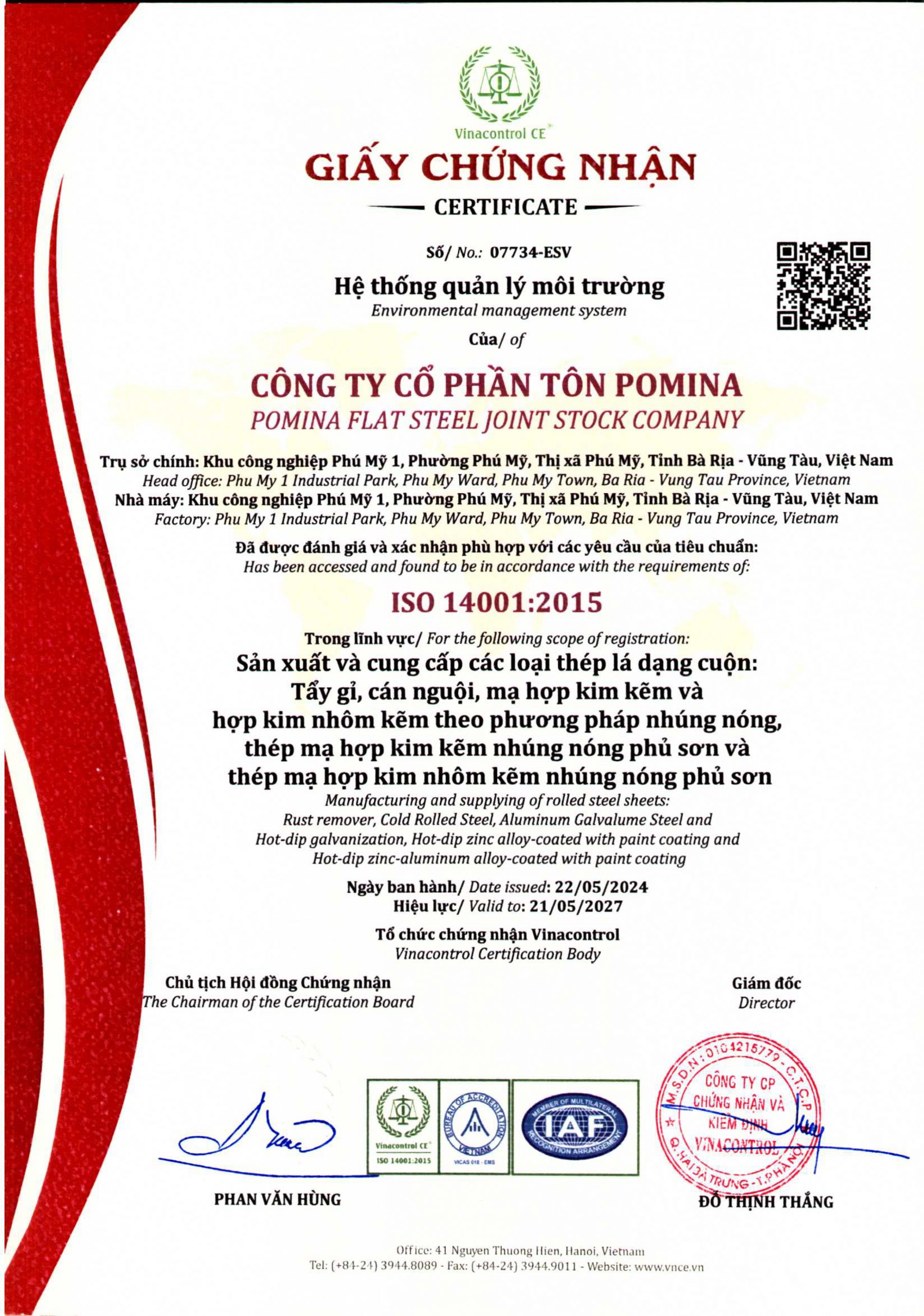

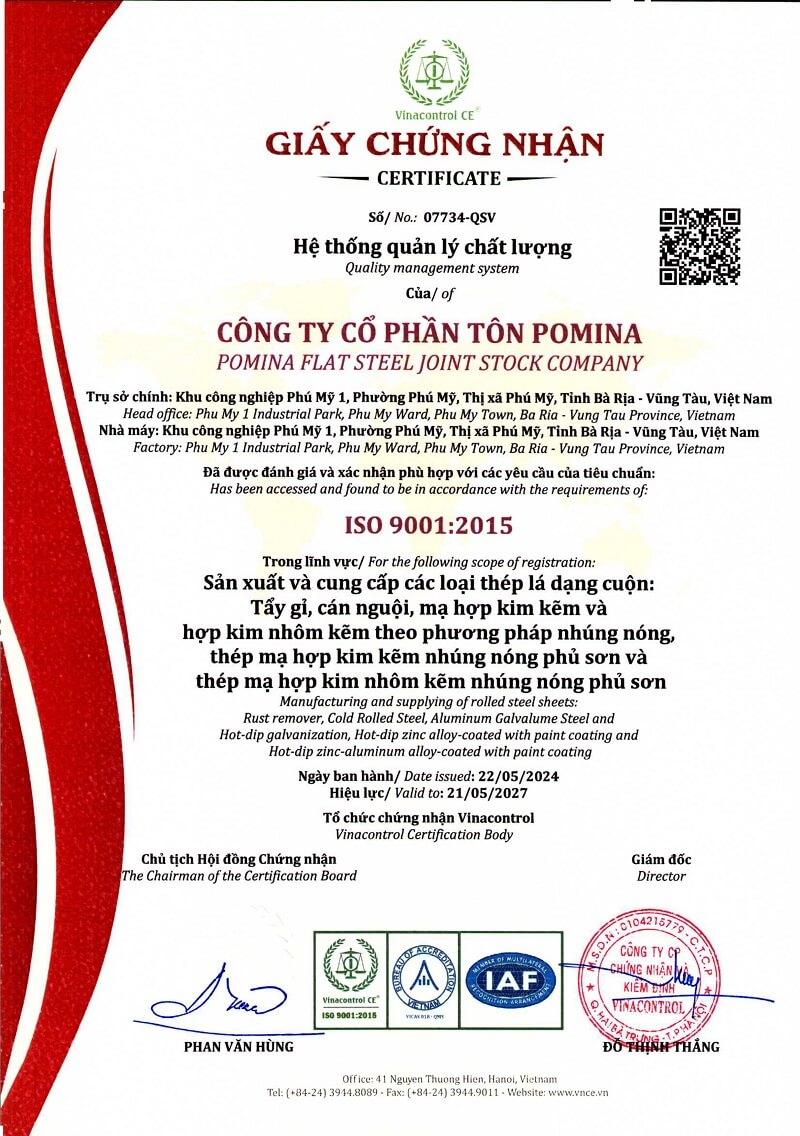

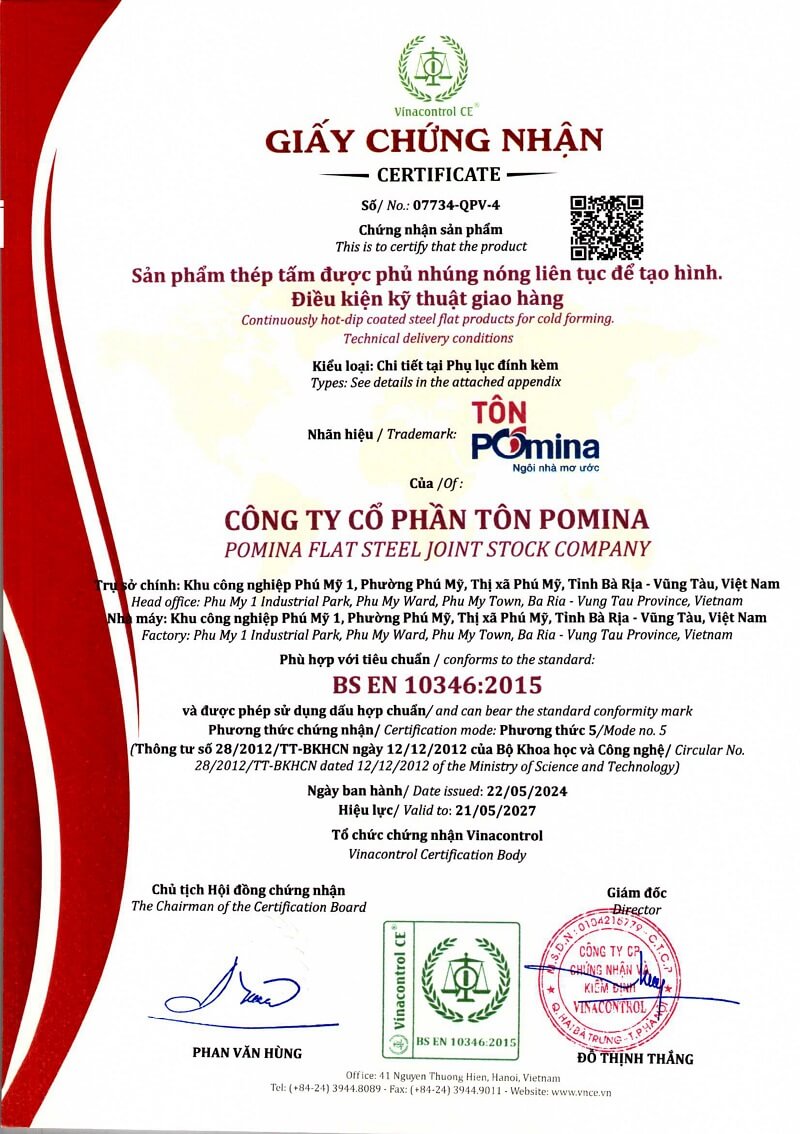

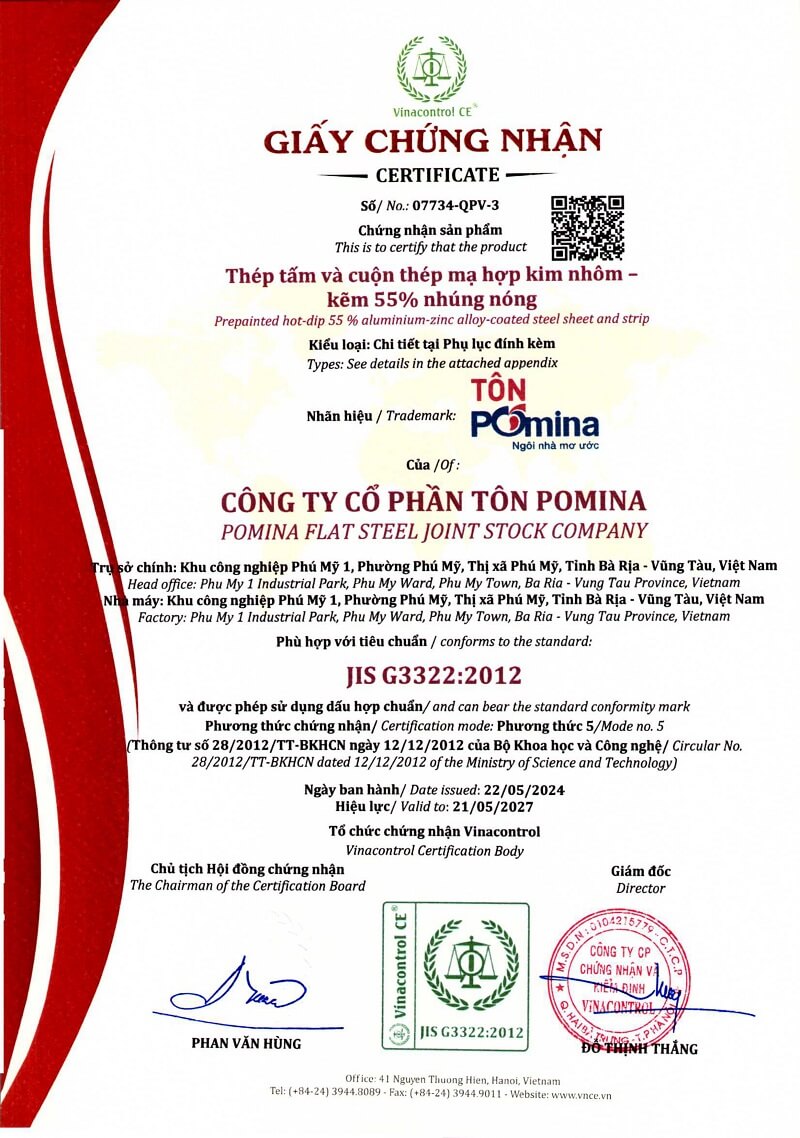

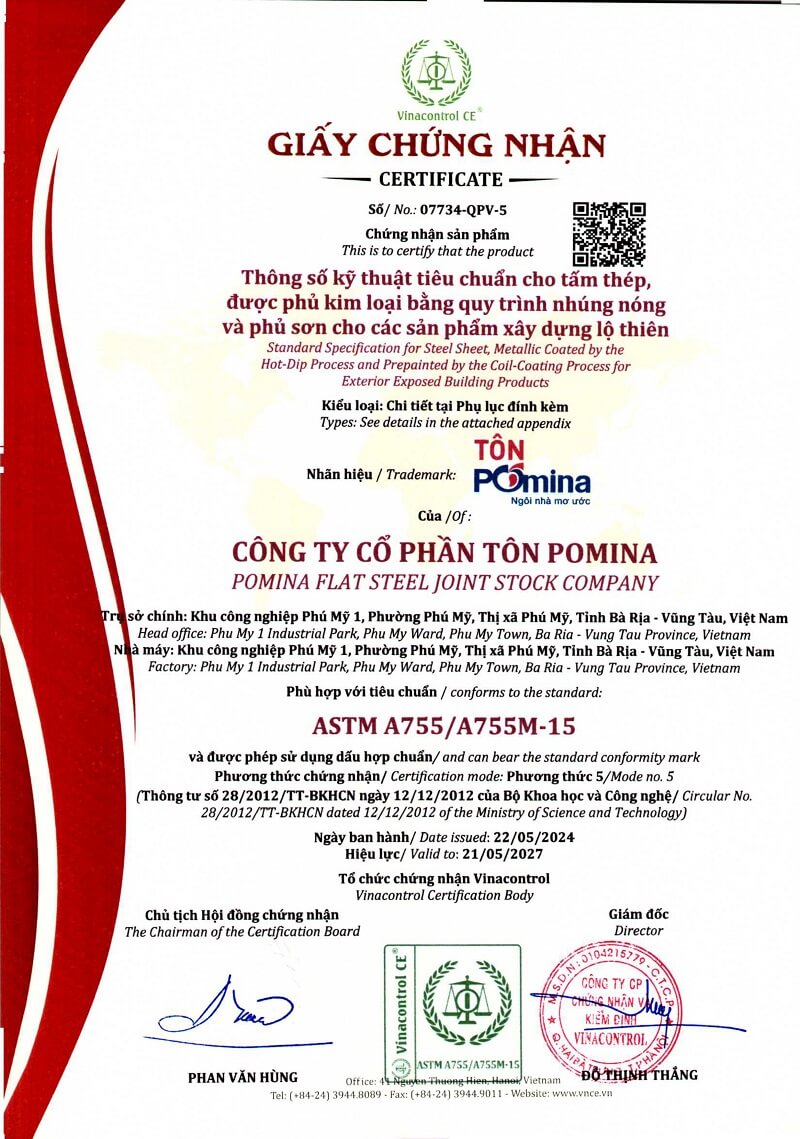

The product is manufactured according to a strict process to meet technical standards such as: ASTM A755 (USA), JIS G3322 (Japan), BS EN 10346 (Europe)

3. Outstanding advantages

- Ensuring product quality: Because it has undergone a rust removal process, hot rolled steel coils are well preserved when stored. When used, the quality of the steel is still guaranteed, without affecting the quality of the concrete and the quality of the next coating layers.

- Increasing the adhesion between the steel and the coating layer: Because the surface has been cleaned, the adhesion between the steel and the coating layer is also better.

- Increasing the aesthetics of the finished product: The steel surface has a certain degree of reflectivity, so it has a higher aesthetic value than regular hot rolled steel coils.

4. Practical application

PO (Pickled & Oiled Steel) products are used in many manufacturing fields such as:

- Cold-rolled steel coil production

- Motorcycle and bicycle spare parts production: Production of sprockets from high-hardness, high-durability steel

- Mechanical components production: Durable, beautiful mechanical accessories

- Steel pipe production: Round steel pipes made from oil-coated pickled steel coil

5. More information

Products are controlled by ISO 9001:2015 system. For further detail, please contact hotline 0906 687 917.