Information

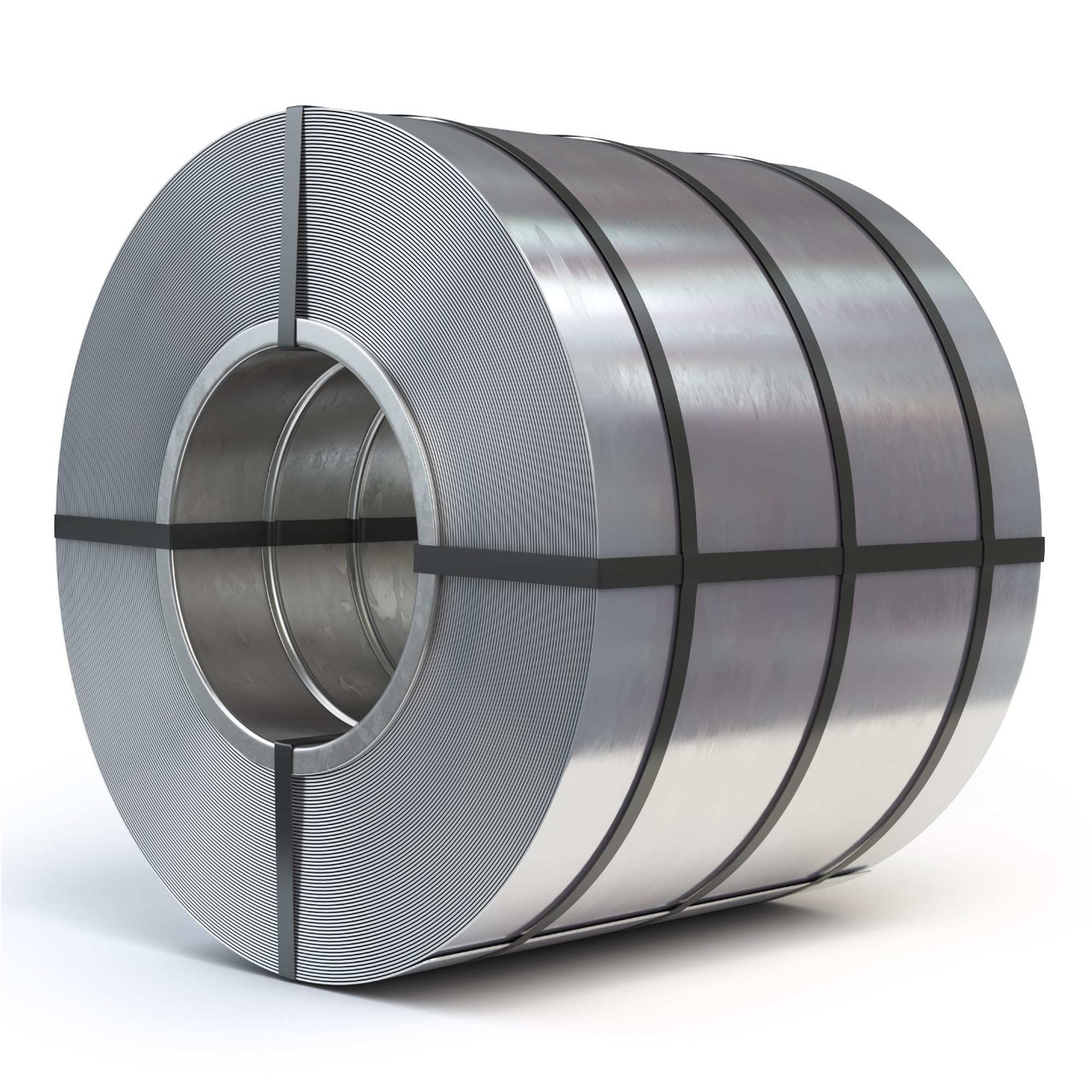

1. What is Cold-rolled coil?

Cold-rolled coil is a steel product rolled thin from hot rolled steel coils, then through the stages of flattening, cleaning and rolling precisely to the required thickness. Structural characteristics:

- Steel grade: G300 – G550

- Surface: smooth, no impurities

- Common thickness: from 0.30mm to 0.50mm

- Width: 914mm – 1,200mm

- Coil or cut sheet form as required

2. Cold-rolled coil production process

- Step 1: Hot rolled steel is passed through a pickling line to remove rust on the surface, then cleaned and coated with a layer of oil to protect the surface. Hot rolled steel after being picked and oiled is called pickled and oiled steel (PO).

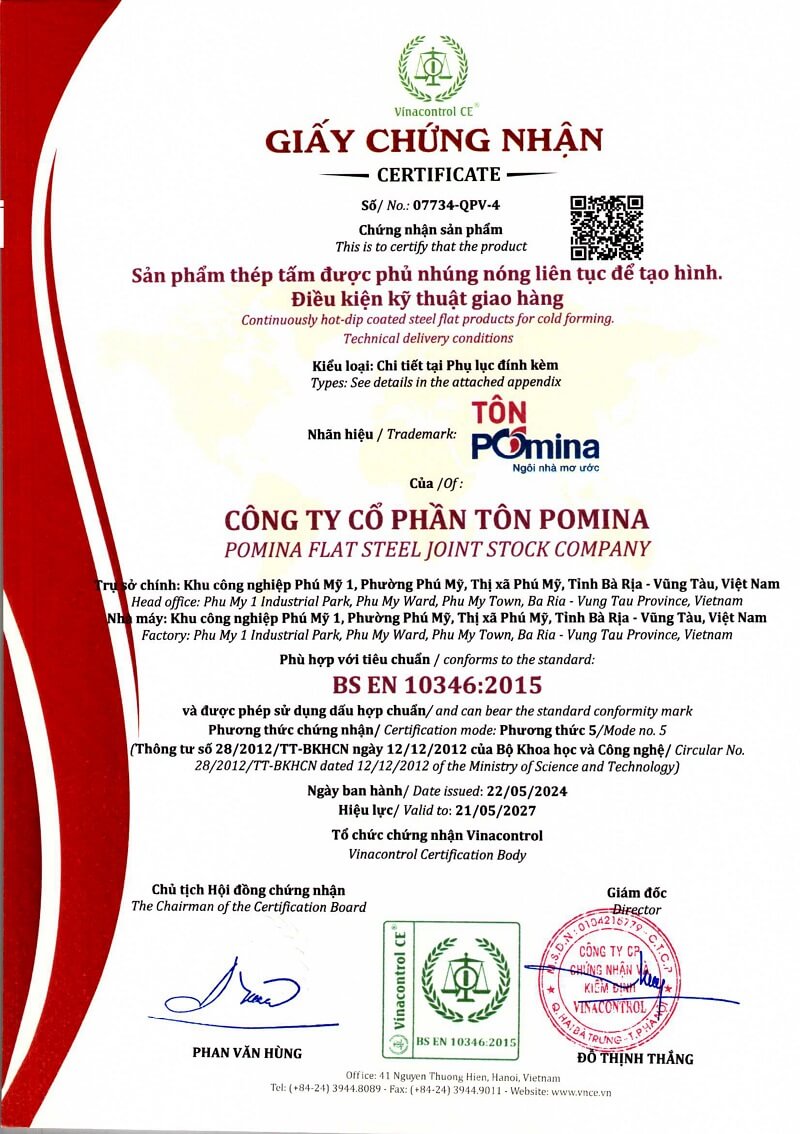

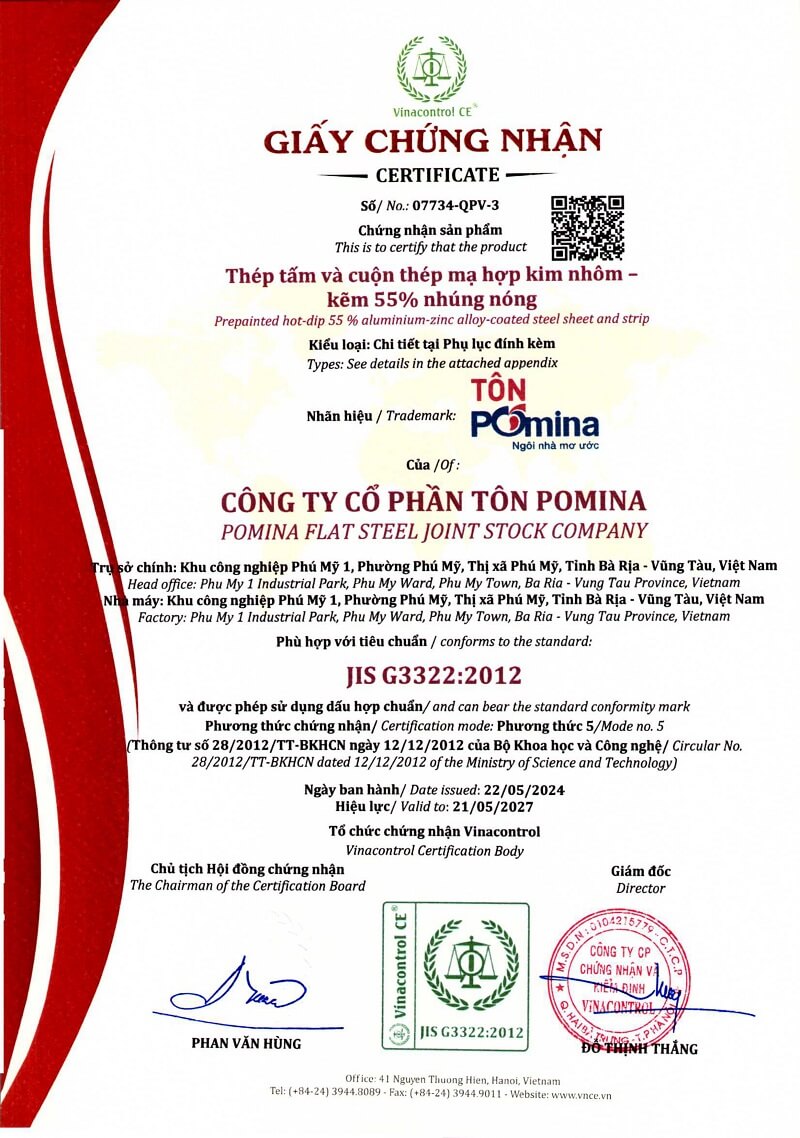

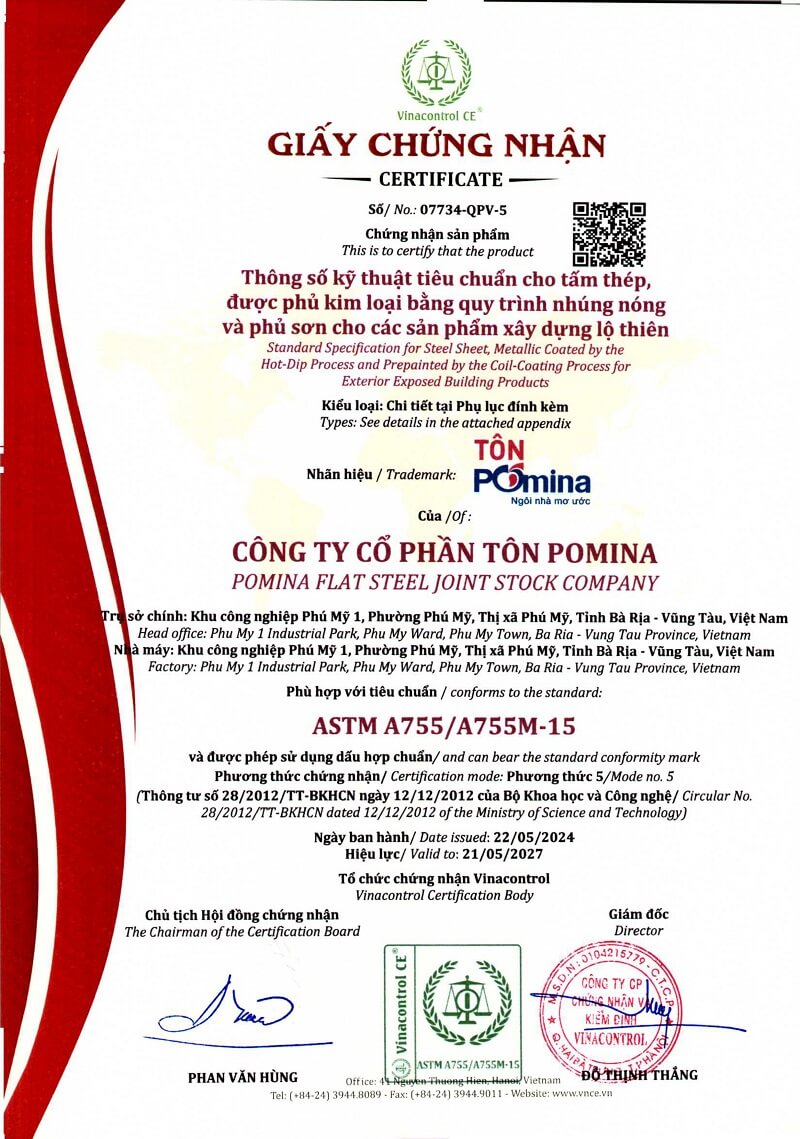

- Step 2: Pickled and oiled steel (PO) is passed through a cold rolling line to produce cold rolled steel products with required sizes. The products are manufactured according to strict processes to meet technical standards such as: ASTM A755 (USA), JIS G3322 (Japan), BS EN 10346 (Europe)

3. Advantages of cold-rolled coil

- Steel has high mechanical properties with standard hardness, high durability, and extremely good resistance to force and impact.

- The surface of the steel always reaches a smooth level and high gloss

- The steel has a very eye-catching bright color, low carbon content helps the steel to be more durable

- Cold-rolled coil has very good resistance to force and impact

- In addition, the edges of the steel are always trimmed neatly, sharp and not rough or wavy

4. Practical applications

- Semi-finished raw materials for the production of galvanized steel coils, cold-rolled steel or color-coated cold-rolled steel thanks to their high durability and good load-bearing properties

- Toolboxes, racks, lamps, stairs

- Metal furniture such as wardrobes, beds, aluminum frames for glass doors

- Manufacture of specialized construction machinery and equipment

- Construction frames for works ensure long-term durability and high quality

- Deep-drawn and deep-drawn machine parts

- Automotive and aircraft spare parts.

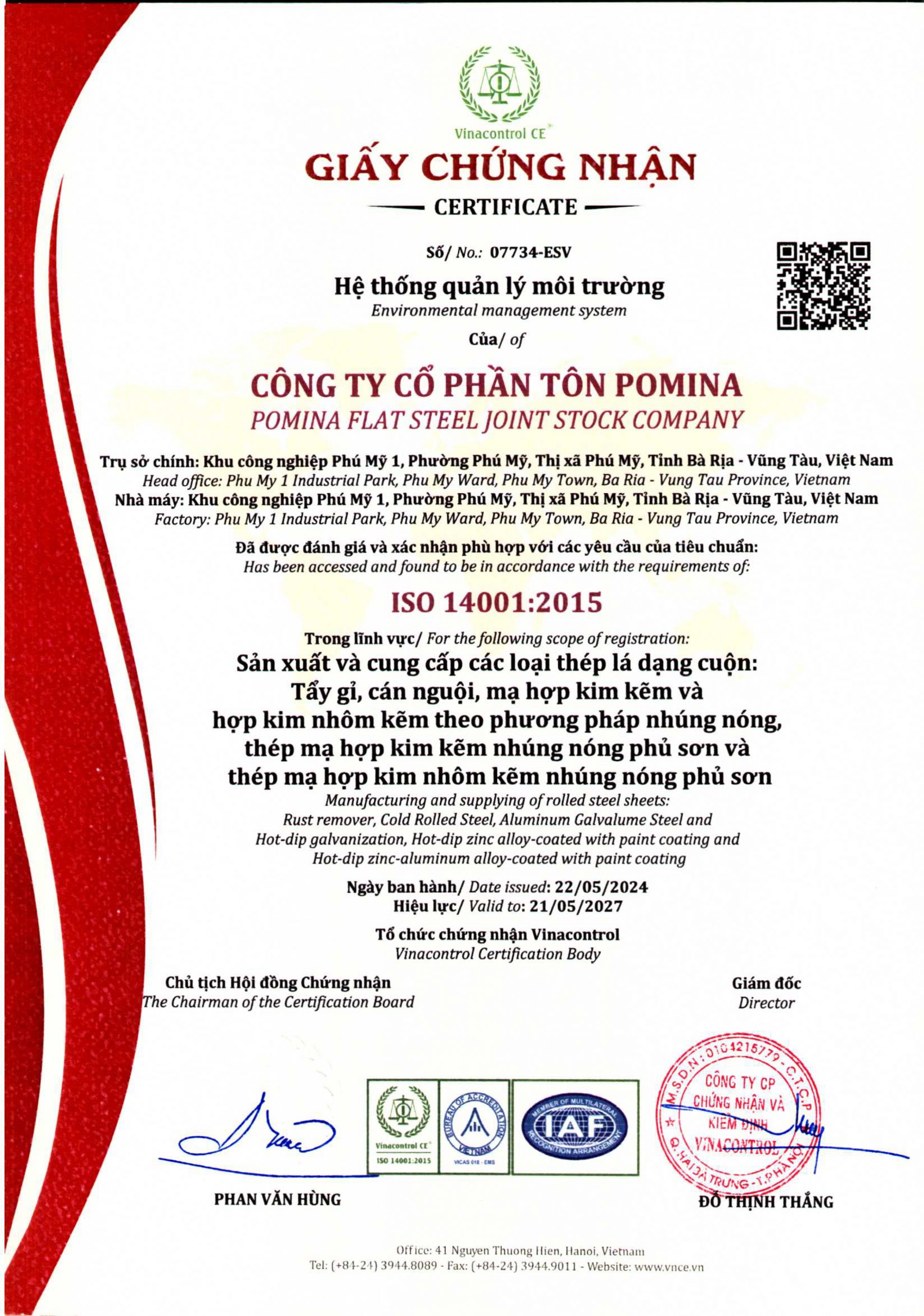

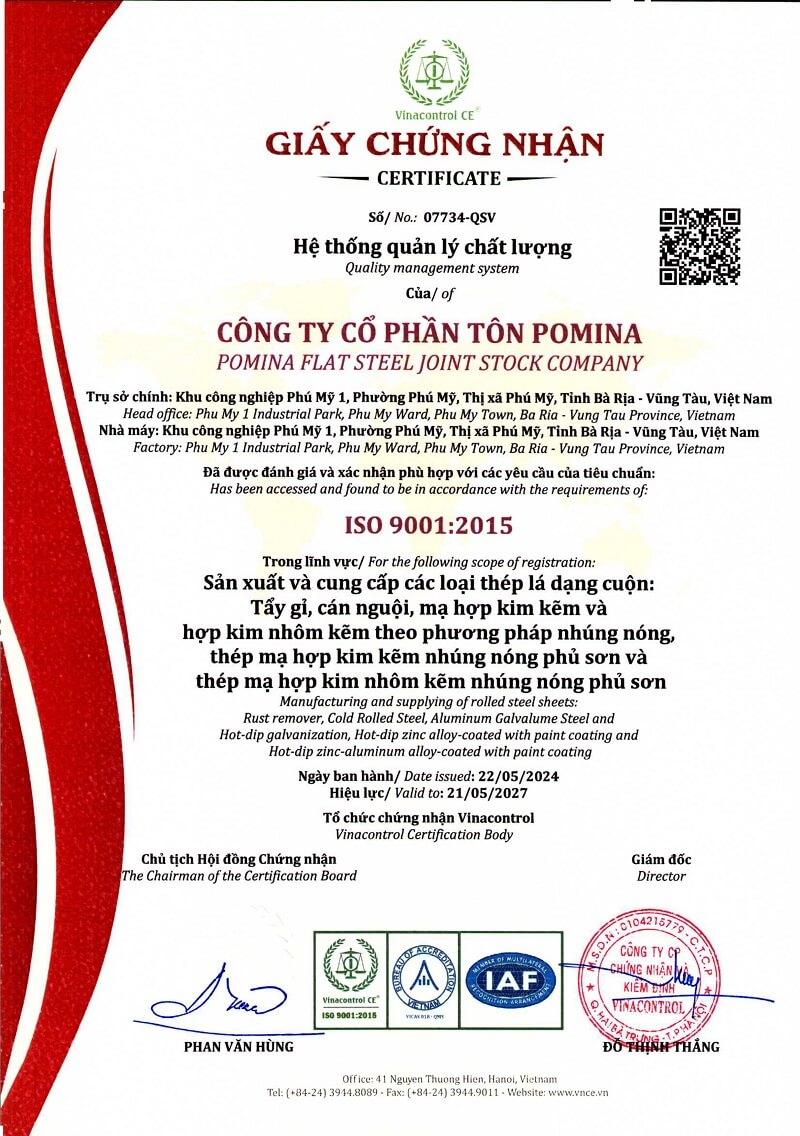

5. More information

Products are controlled by ISO 9001:2015 system. For further detail, please contact hotline 0906 687 917.